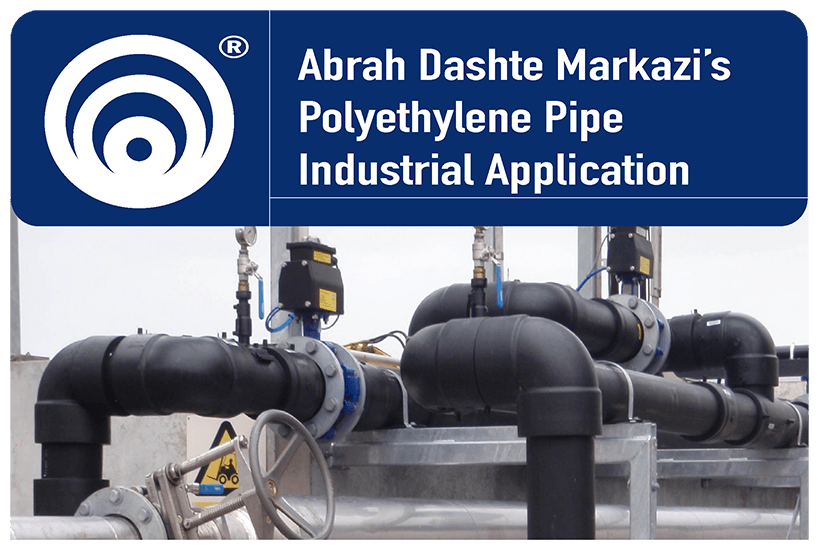

Industrial PIPE | HDPE & PE-RT PIPE in industrial piping systems

Industrial PIPE | HDPE & PE-RT PIPE Application in industrial piping systems

Industrial PIPE Should meets Special requirements to Be able to fulfill industrial requirements of industrial piping systems.

Abrah Dashte Markazi As HDPE PIPE and PE-RT PIPE Manufacturer Especially recommend the use of PE-RT PIPE For temperatures more than 60°C up to 80°C with malfunction temperatures up to 100°C in industrial Application while higher Service Temperature is required PE-RT testing of one year at 110°C allows for extrapolation of 50 years at 70°C. Typically the basis of the extrapolation is the logarithmic average of the five longest test times at the highest test temperature. but if your temperature is 60°C and below HDPE PIPE Such As PE100-RC and PE100 And PE80 are a matter of choice with surface or underground installation.

HDPE’s molecular structure and ductility result in excellent resistance to abrasion, gouging and scratching HDPE pipe are available for pressures up to 25 bar (365 psi) or even more if demand and constant service temperatures up to 60 degrees Celsius 140° F in Normal HDPE PIPE And now With PE-RT PIPE temperatures up to 80°C with malfunction temperatures up to 100°C. Please see the HDPE PIPE chemical resistance chart in TR-19 for the effects of different chemicals at different temperatures (there isn't still a Chemical resistance chart for PE-RT PIPES while it has much more potential in higher temp).

the industrial pipe must also be corrosion and abrasion-resistant. the industrial pipe must be flexible and easy to install and maintain a high flow coefficient throughout the industrial pipe service life of 50-100 years. And industrial pipe must not leak.

HDPE is one of the most chemically inert plastics and therefore is extremely resistant to chemical attack and corrosion as an industrial pipe.

HDPE PIPE can resist the corrosive effects of soils or effluents with pH range from a very acidic 1.5 to a very caustic 14 as an industrial pipe.

HDPE pipe is often specified where acidic or alkaline native soil conditions exist, HDPE Pipe and fittings shall be used in industrial piping systems most meets or exceeds the requirements of DIN 8074 or ISIRI 14427 or ASTM D3350 Highly Depend on Application Polyethylene pipe as an industrial pipe

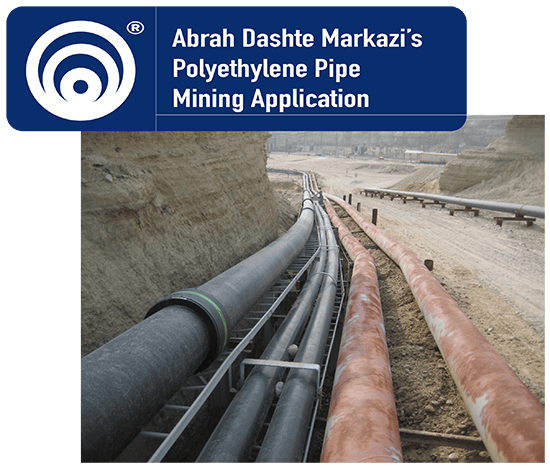

HDPE pipe as an industrial pipe is corrosion resistant and has a long history of use as an abrasion-resistant material in mining applications. It is lightweight, easy to install, and reduces the number of fittings needed in a system because of its flexibility. With Abrah Dashte Markazi's HDPE PIPE, you get all of these benefits. HDPE pipe is significantly more resistant to abrasion than RCP and CMP pipe Because of the hazardous nature of some chemicals being transported, it is imperative that the system not leak.

Heat fusing polyethylene pipe produces a leak-free joint that is as strong if not stronger than the pipe itself in tension and pressure applications. These joints are self-restrained. They need no thrust blocks or restraint harness except where the pipe attaches to a non-polyethylene system.

Industrial PIPE | Industries Currently Using HDPE & PE-RT PIPE in their industrial piping systems

- Fertilizer

- Paper and Pulp Manufacturing

- Power Plants

- Petrochemical

- Glass

- Semi-Conductor - Wafers

- Plastic resin Manufacturers

- Dredge operators

- Clean and ultra-pure water process

- Tank farms - fire loops and mains

- LNG (Liquefied Natural Gas)

Industrial PIPE | HDPE & PE-RT PIPE Applications in Industrial piping systems

- Acid/Caustic Lines

- SX Acid Mining

- Factory Mutual Piping - Fire loops and mains

- Organic Chemicals

- Inorganic Chemicals

- Hazardous Waste

- Wastewater

- Process Water

- Dual Contained Systems

- Cooling Water

- Acid bath

- Barge loading and unloading Tank storage

- Dual Containment Piping Systems

- Aeration

- Tailings lines

- Liquor, bleaching, and caustic acid lines

- Pipe rehabilitation in both plant and out of plant piping.

- Dredge piping

- Pit dewatering

- Fertilizer

- Power Plants, fresh water and discharge. Spent fuel slurry (fly ash and bottom ash)